Contact sales for pricing

PVP Original K30, Povidone, Polyvinylpyrrolidone 50 kgs

PVP Original K30, Povidone, Polyvinylpyrrolidone 50 kgs

What is PVP original K30, Povidone, or Polyvinylpyrrolidone?

Ingredient Depot's PVP K30, Povidone, or Polyvinylpyrrolidone is a synthetic polymer known for its versatility. Offered as a near-white, free-flowing powder, it is characterized by a faint, intrinsic scent and is essentially tasteless. Its unique property of being soluble in both water and numerous organic solvents, combined with a robust binding capacity and the capability to form soluble complexes, makes it unparalleled among synthetic colloids. Ideal for various applications due to its adaptability and solubility properties.

How is PVP K30, Povidone, or Polyvinylpyrrolidone manufactured?

PVP or Povidone is produced through a polymerization process. This polymerization can be carried out in water or organic solutions. Through the initiation of organic or inorganic radical starters, the resulting polymers span an extensive range of molecular weights. The outcome is a versatile polymer that stands out due to its solubility in various solvents and its substantial binding power, making it indispensable for the pharmaceutical sector.

Tablet Binding

The application of K30 in high shear mixers or fluid-bed granulators yields granules that are notably hard, offering a smooth flow and minimal fines. This result is a binding strength, ideal for sturdy, robust production output. In terms of binder quantities, K30 is typically between 2% and 5% relative to the tablet weight.

Also suitable for direct compression, even without granulation. The process calls for a specific humidity level, given the need for the powder mixture to maintain a certain moisture content for optimal binding. Additionally, K30 alongside microcrystalline cellulose enhances tablet hardness and reinforces their edges.

For lactose monohydrate tablets with a 3% PVP, Povidone, or Polyvinylpyrrolidone composition via wet granulation, the polymer also proves valuable. It's apt for modern procedures such as fluidized-bed granulation. Given its relatively low viscosity, solutions of PVP can be rapidly prepared and easily sprayed, resulting in uniformly hard, dust-free granules. When pigmentation is involved in the spraying process, PVP, Povidone notably enhances the distribution of these pigments.

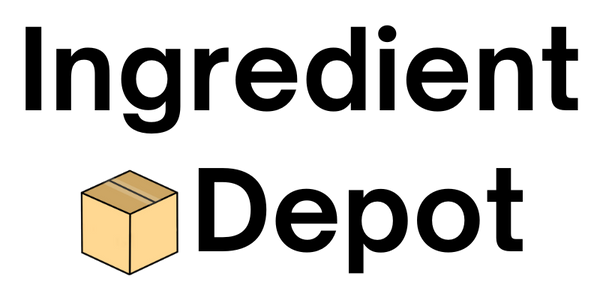

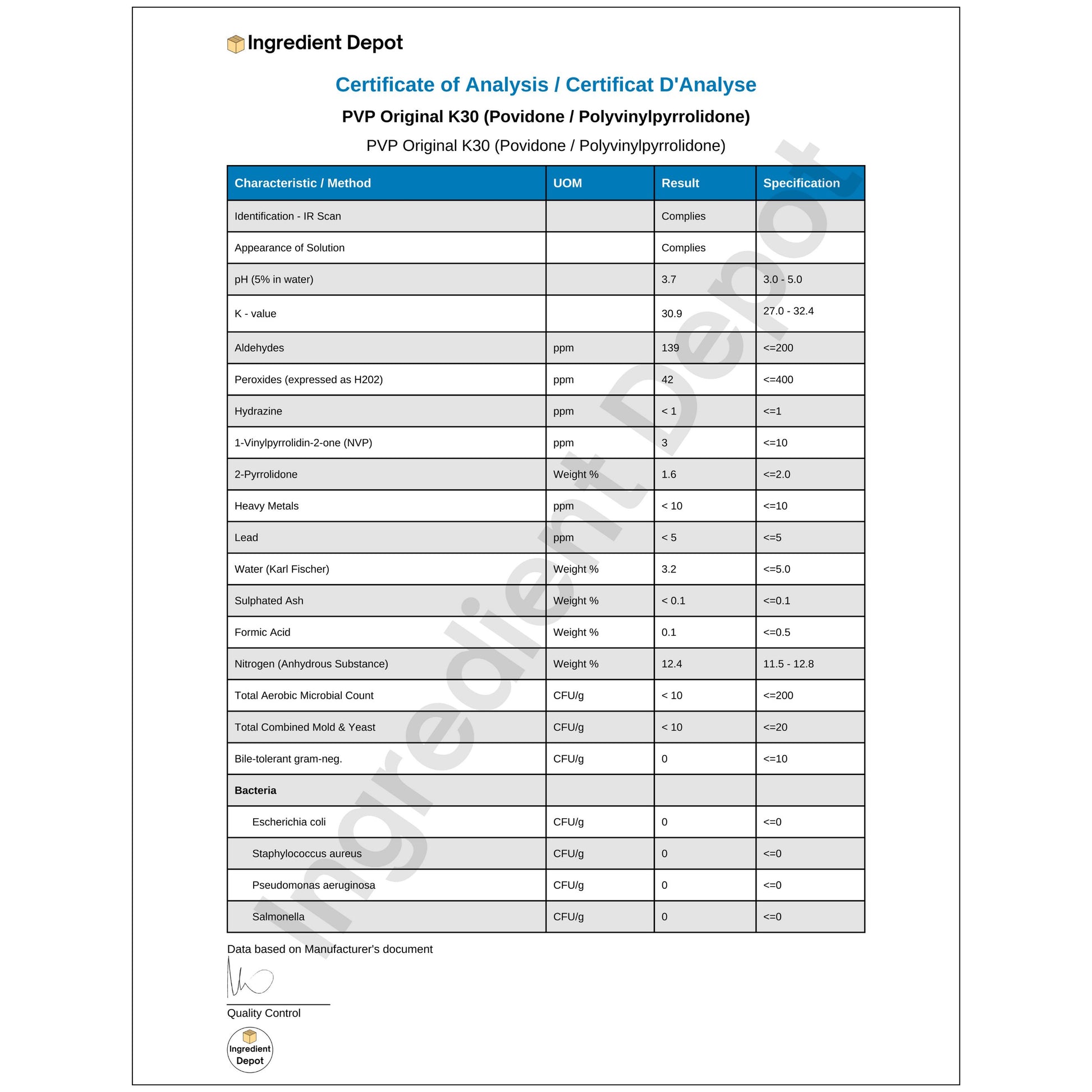

What is the grade and country of manufacture?

PVP K30 offered by Ingredient Depot adheres to the highest quality standards. The product is certified under USP, Ph. Eur., and JP grades. This product is from the United States.

Authorized Applications

- Binder for tablets, capsules, and granules

- Bioavailability enhancement

- Film formation

- Solubilization

- Lyophilizing agent

- Stabilization

- Adhesives

- Stabilization

Preferred Industries

- Pharmaceuticals

- Cosmetics

- Food and Beverage

- Chemicals

- Plastics Manufacturing

- Paints and Coatings

- Textiles

- Printing

- Ceramics

- Adhesives

The solubility dynamics can vary greatly based on the solvent used.

Soluble in:

- chloroform

- cyclohexanol

- ethanol abs.

- glycerol

- isopropanol

- methanol

- methylene chloride

- n-butanol

- n-propanol

- polyethylene glycol 300

- polyethylene glycol 400

- propylene glycol

- triethanolamine

- water

Insoluble in:

- pentane

- carbon tetrachloride

- toluene

- xylene

Particle-size distribution and Bulk Density

In the realm of pharmaceutical technology for solid dosages, the particle-size distribution of used ingredients is pivotal, especially in tablet direct compression.

Particle-size distribution (determined using an air-jet sieve; 5 min, 20 mbar)

- <50 μm approximately 10%

- 250 μm maximum 5%

Bulk density

- 400 – 600 g/l