Code: SAVE20 — 20% OFF

SMCC PROSOLV 50 Silicified Microcrystalline Cellulose 20 kgs

SMCC PROSOLV 50 Silicified Microcrystalline Cellulose 20 kgs

Couldn't load pickup availability

Shipping options, taxes, and discount codes displayed at checkout before payment

What is PROSOLV SMCC 50?

PROSOLV 50 SMCC is a high-quality silicified microcrystalline cellulose (SMCC) product, combining microcrystalline cellulose (MCC) and colloidal silicon dioxide (CSD) in a synergistic mixture. This product is part of the PROSOLV SMCC family, which balances best-in-class compaction and flow for tablet formulations. PROSOLV 50 SMCC is chemically inert, highly compactible, and has a high intrinsic flow. Ideal for high-dose, direct compression formulations, and roller compaction processes.

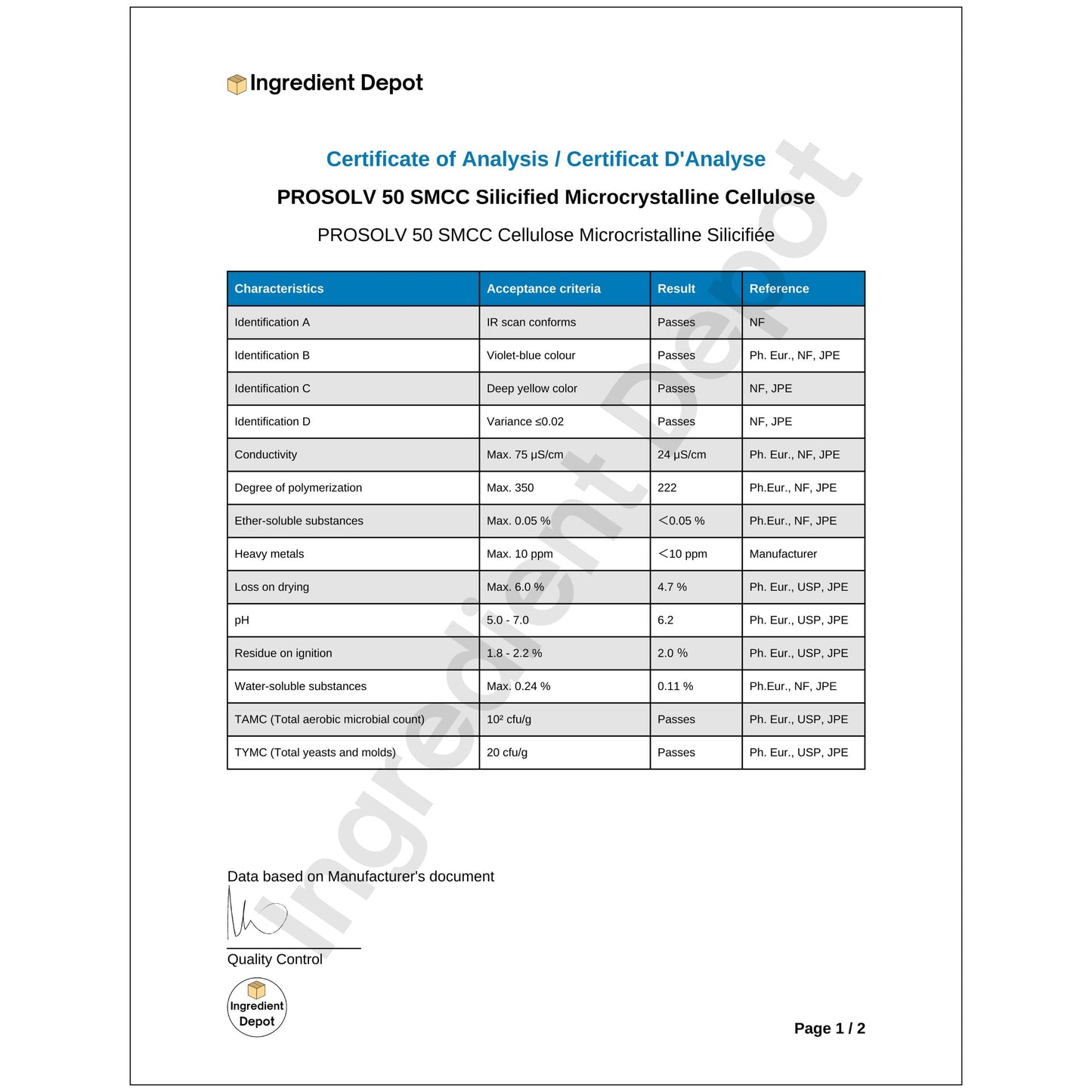

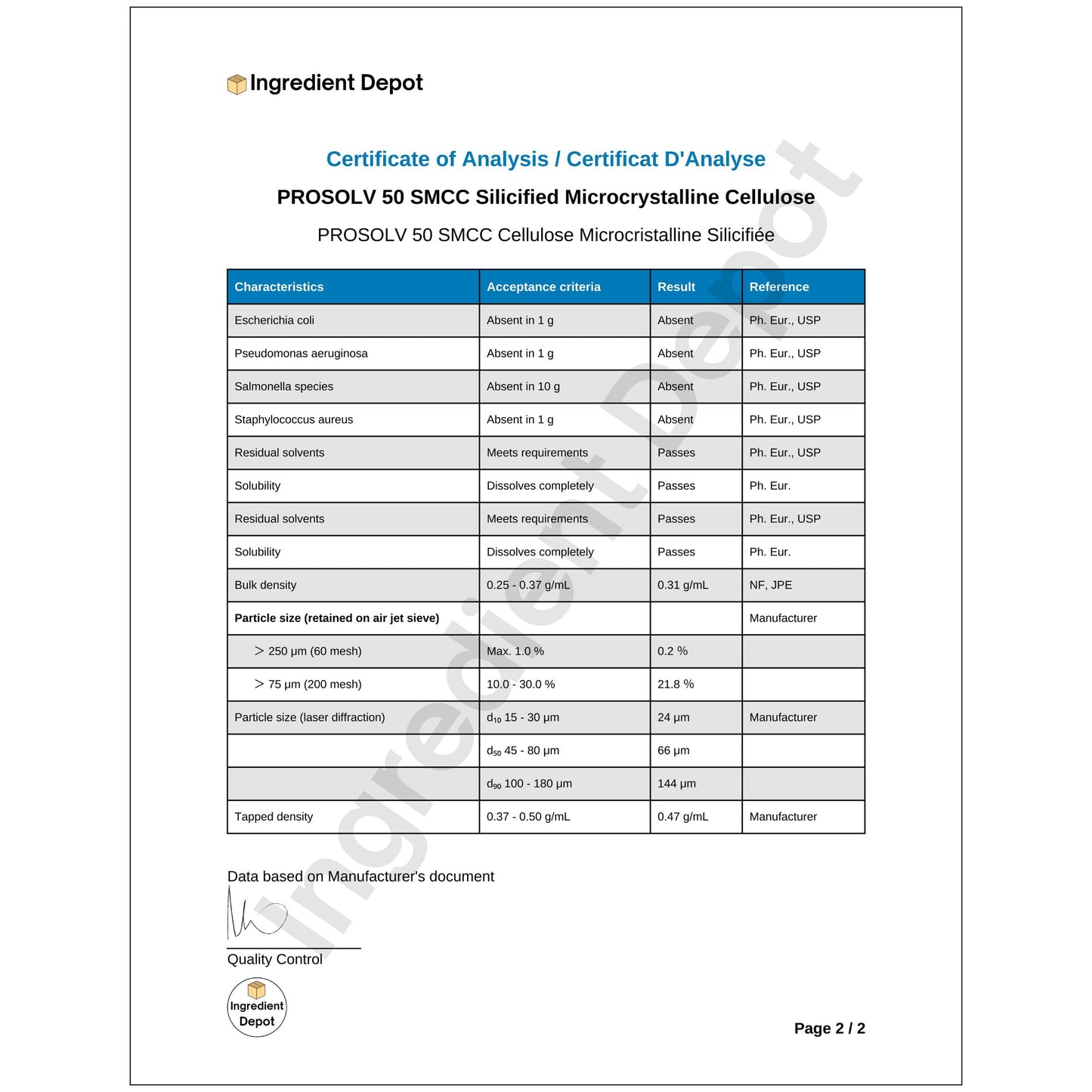

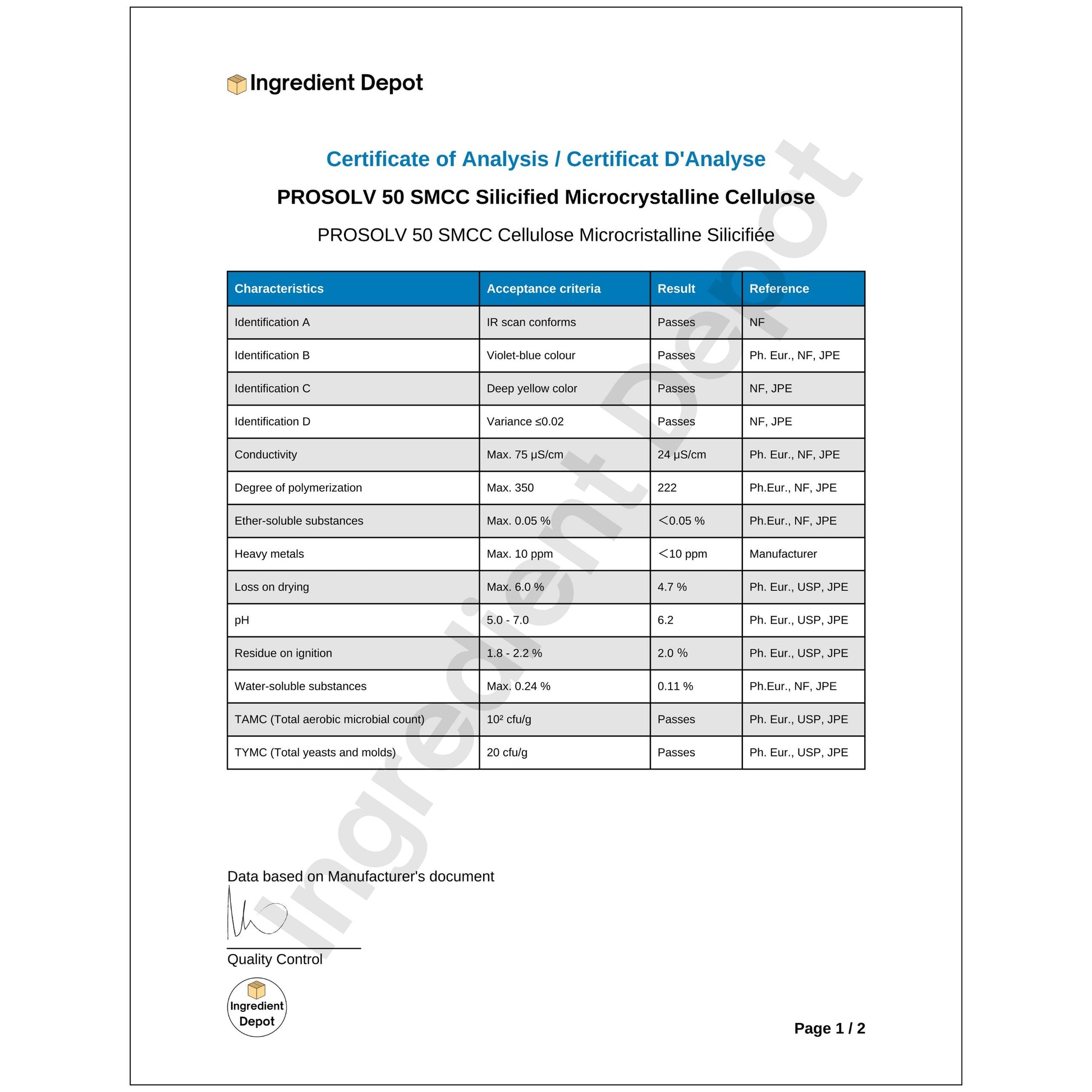

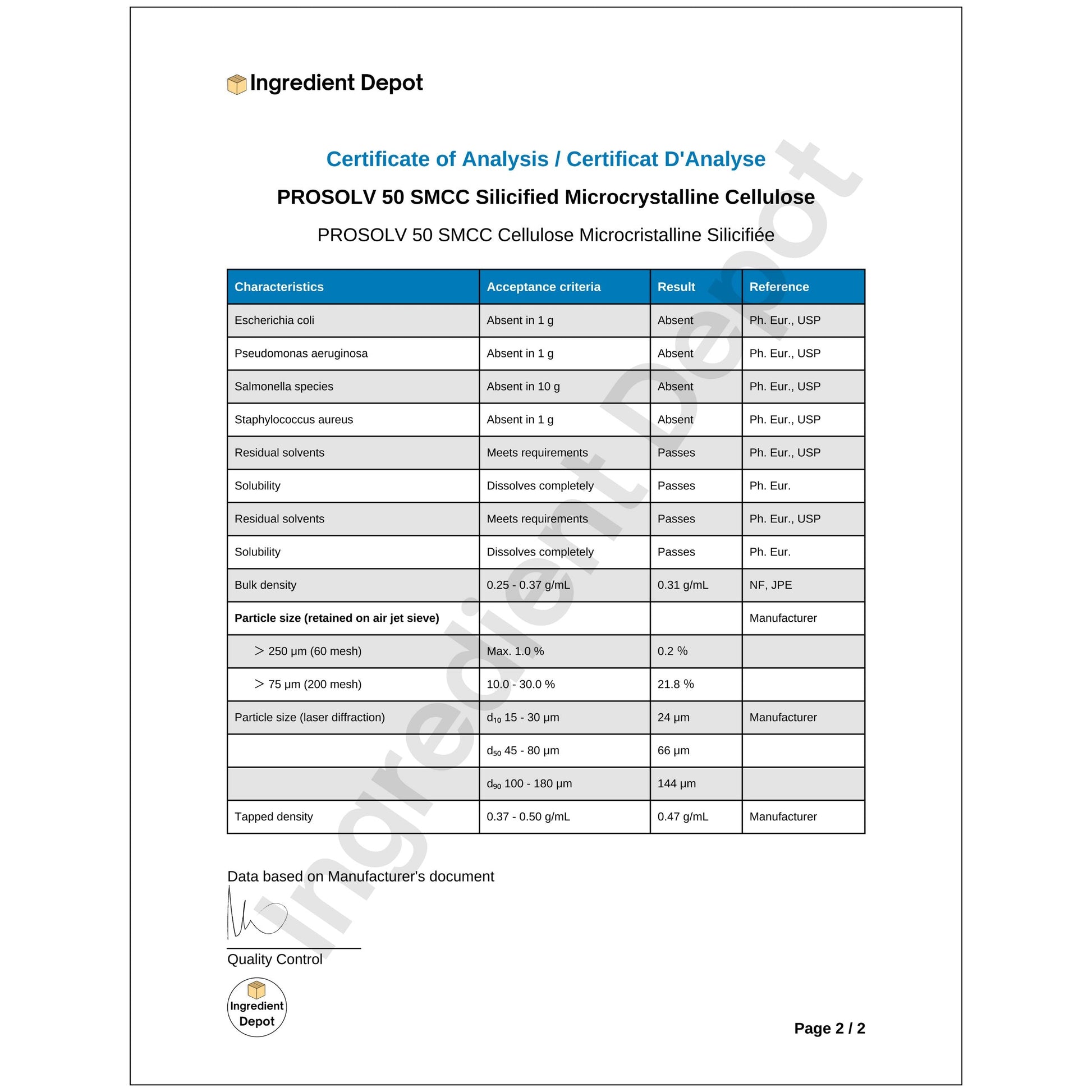

Specs and features for PROSOLV SMCC 50:

- Average Particle Size: 65 µm

- Bulk Density: 0.25 – 0.37 g/mL

- With optimal compaction and decent flow.

How is PROSOLV SMCC manufactured?

In order to manufacture PROSOLV SMCC, microcrystalline cellulose (MCC) is intimately blended with colloidal silicon dioxide (CSD). With the high-speed tableting process, the product has much better powder flowability than traditional MCC grades of the same particle size. Despite low doses and micronized active ingredients, PROSOLV SMCC's unique surface structure ensures excellent blend homogeneity and content uniformity.

Advantages

- PROSOLV SMCC exhibits a 5 times increased surface area thus improving the outstanding binding properties of MCC

- Flowability and tablet strength are superior to VIVAPUR MCC

- Reduces the amount of excipients used, resulting in savings

- Insoluble in water, acetone, or anhydrous ethanol

- Mixing characteristics are enhanced

- Resulting in optimized uniformity

- Disintegration time is shorter

- Brightness is high

Applications

- Formulations that use direct compression

- Processes for roller compaction

- Formulations with a high dose

- Tableting at high speeds

- Direct compression

Preferred Industries

- Food and Beverage

- Pharmaceutical

- Nutraceutical

- Cosmetics

- Chemical

Packaging in 20 kgs box: The PROSOLV SMCC 50, 20 kgs box, is a convenient packaging size for businesses of all sizes, offering easy handling and storage while ensuring product integrity and quality. Every PROSOLV SMCC 50 box's content is sealed and includes the PROSOLV SMCC 50 marking.

Grade and Country of Manufacture

PROSOLV SMCC 50 conforms to the Silicified Microcrystalline Cellulose, NF grade, ensuring a high-quality product. Manufactured in North America and adhering to strict quality and safety standards.