Code: SAVE20 — 20% OFF

SMCC 50 Silicified Microcrystalline Cellulose - USP/NF Grade 10 kgs

SMCC 50 Silicified Microcrystalline Cellulose - USP/NF Grade 10 kgs

Couldn't load pickup availability

Shipping options, taxes, and discount codes displayed at checkout before payment

What is SMCC 50 - Silicified Microcrystalline Cellulose?

SMCC 50 Silicified Microcrystalline Cellulose is a high-quality excipient used in pharmaceutical manufacturing. It combines 98% Microcrystalline Cellulose and 2% colloidal silicon dioxide, providing enhanced flowability and compactibility. Ideal for direct compression, it simplifies the tablet formulation process.

How is Silicified Microcrystalline Cellulose manufactured or produced?

SMCC is produced using co-processing technology, ensuring a uniform distribution of colloidal silicon dioxide on the surface of microcrystalline cellulose particles.

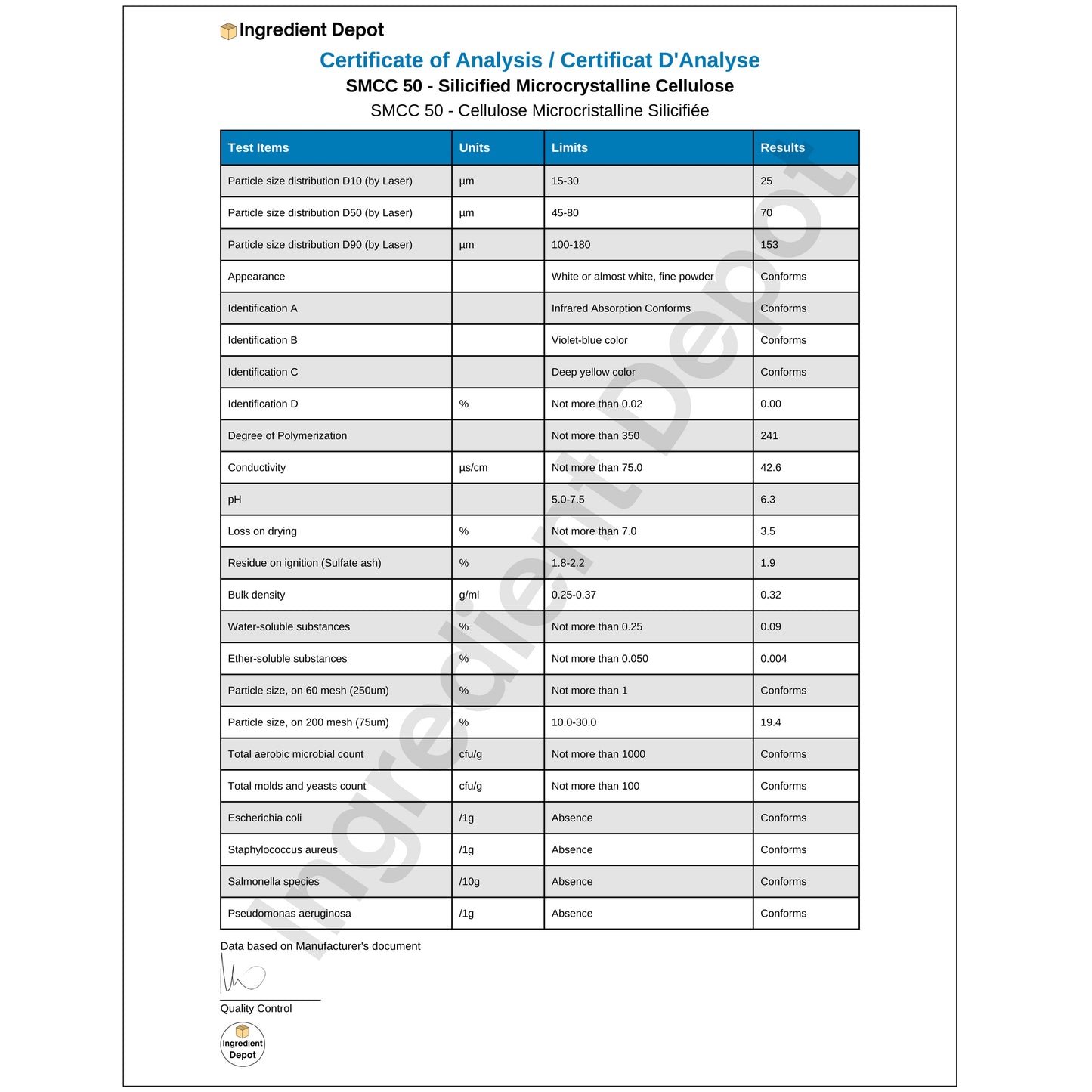

Particle size distribution (μm)

- Laser D10: 25

- Laser D50: 70

- Laser D90: 153

Key Specifications from COA

- Bulk density (g/ml): 0.32

- Loss on drying (% w/w): 3.5

How is it packaged?

The 10kg plastic pail is an excellent choice for larger scale needs, offering robust packaging and convenient access with its reclosable lid, ensuring quality and quantity in balance.

Applications

- Direct compression tablet manufacturing

- Dry granulation processes

- Pharmaceutical formulations

- Nutraceutical products

- Multiple-Unit Pellet Systems (MUPS)

Industries

- Pharmaceutical manufacturing

- Nutraceutical production

- Healthcare sector

- Medical research and development

Grade and Country of Manufacture

Manufactured in China, SMCC 50 adheres to the manufacturer's Grade USP/NF standards, ensuring global compliance and quality for pharmaceutical applications.